Our Products

From our experience in supplying the Ultrasonic Cleaning Machines more 20 years.

Pasuda has set our products to be 8 categories which are:

In your production line, whether you are using the ultrasonic in the cleaning process or you have never used the ultrasonic but you have the cleanliness problems. We would like to introduce our products and services support you.

The cleaning process looks simple in fact there are many concerned factors to let the parts are cleaning and drying perfectly. Without the experience it might be taken long time for analyzation the root causes of the remain contaminate or not dry perfectly.

“To select the proper ultrasonic power and frequency for each parts” is one of importance of design the cleaning machine. Not only the ultrasonic design but also the cleaning fluid solution, and drying process are concerned your products quality, running cost, and working environment.

PASUDA can support you for all above mentioned factors. Let us inform you for further information as per the following case study projects.

I. To Improve the Existing Cleaning Process

In recently, there are many new part design, and almost of new design are come from changing the parts material to let the Products to be much lighter weight, or cost down.

For example, the material has been changed from Stainless Steel to be Aluminum or Titanium, the design is more complicate or have blind hold, all of this new product design has changed. So, the ultrasonic cleaning process has to redesign or modify to be proper for the new process, such as Ultrasonic power up, renew the ultrasonic low frequency to be high frequency and low power or let the ultrasonic face to the complicate position on the parts.

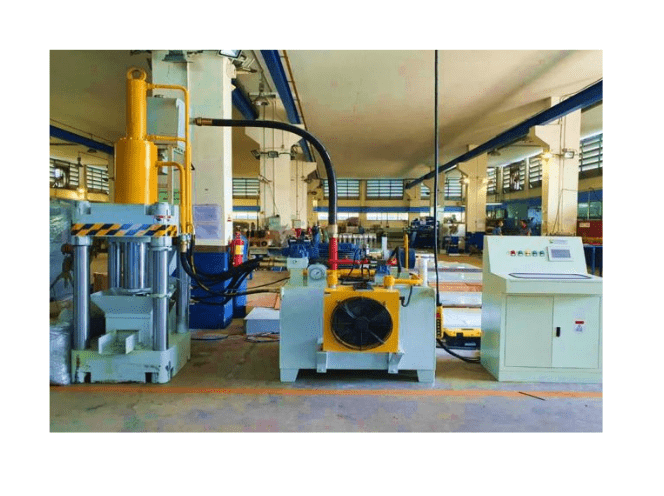

Not only ultrasonic cleaner, but also other hi-pressure spray cleaning machines, Ultrasonic in coating machine, passivation machine, chiller for hydrocarbon cleaning machine, distillation, recycle machine.

In addition, for drying process, PASUDA can help you to improve the drying from De-watering by hot-air blow dryer to be vacuum dryer.

Since 2007, we have designed and supplied the automatic ultrasonic cleaning machine for several industries; Jewelry cleaner, Watch parts cleaning machine, Electronics parts,

PCB stencil cleaner, Hard Disk Drive (HDD) parts, Camera parts and lens, Air-Conditioner parts cleaning machine, Automotive Parts, Medical parts, such as Surgical Needle, Surgical tools cleaning baht, Injection Needle ultrasonic cleaning machine, Dental ultrasonic cleaner, Medical rubber glove and mold cleaning machine, also for Food industry, oily tray in the process, Herb and Vegetable cleaning machine.

II. To Design for the New Cleaning Process

As a good start is a half way of success. PASUDA can support you if you would like to design for the New ultrasonic cleaning process by arranging the cleaning trial on our demonstration machines complete with the cleaning trial report by our specialist engineers who have experience in cleaning process and chemical.

We can support you the cleaning trial and help you to design for the new cleaning machine, cleaning fluid solution; detergent, solvent, hydrocarbon base and also help you to send after trial parts to the third party laboratory test results, to let you ensure the cleaning process performance, all data are for your consideration for the return of investment of the new cleaning machine.

PASUDA can help you design the ultrasonic cleaning machine whether your products material is metal parts; stainless steel, aluminum, copper and brass parts cleaner, or plastic, glass, also special specific light weight material

III. To Design for all related process to be the Automatic Line

For the new industrial process design concept, the more automatic production line, the more quality control and cost reduction you are.

PASUDA can support you to design your current manual cleaning process to be automatic cleaning line by robot, conveyor, pick and place automation, as well as inking each process to be automatic whether it is before and/or after cleaning process by machine program, using worldwide electronics parts, to support ioT, with good PLC and touch screen, for saving running cost, and concerned safety purpose.

As per the above, and according to our experience, we have the specialist engineers team and ready to support you if you have any inquiries please feel free to contact us at any time.

Detergent

For a total cleaning solution, we provide a variety of Detergent / Soap (Water Base), Hydrocarbon Base, and Solvent Base to help you with your cleaning process, whether you need to clean Aluminum, Steel, Brass, Copper, SUS, and Others.

- Detergent / Soap with high efficacy is environmentally friendly, with a combining power of herbal-based surfactant and careful selections of other hybrid surfactants which make it possible to clean the tough greasy stain in many industries. Can use applicable for multiple cleaning-degreasing purposes.

- Hydrocarbon is a highly purified narrow cut of synthetic hydrocarbon cleaner/degreaser specially developed excellent cleaning, high recovering & drying performance, and extremely low odor & toxicity.

- A solvent is a cleaner/degreaser specially developed for excellent cleaning, high drying performance, and quick dry.