Our Services

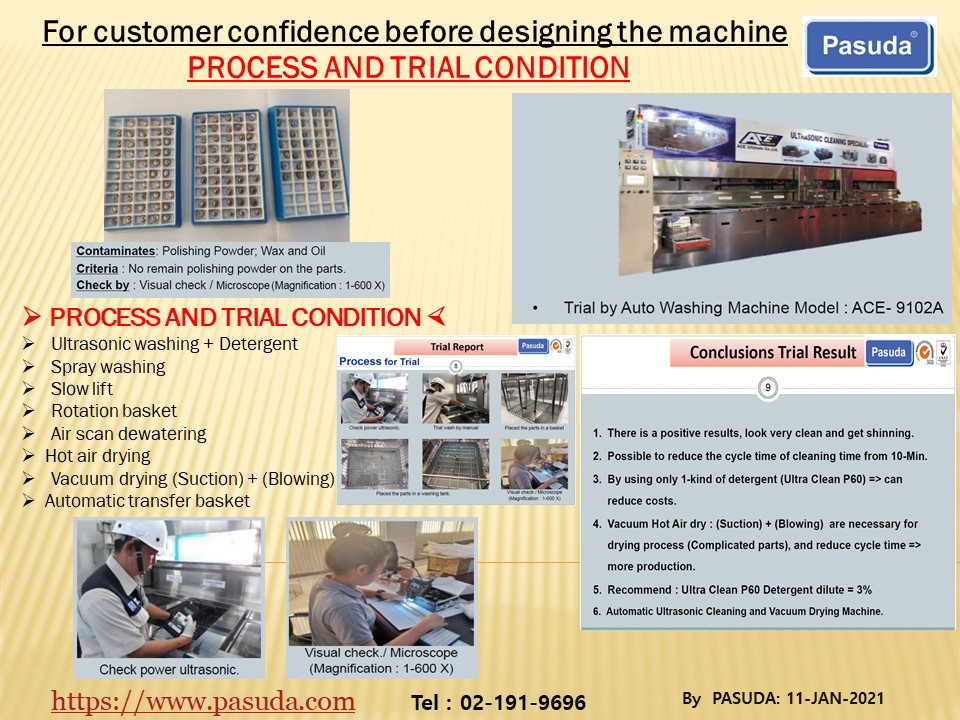

Cleaning Trial for best solution

We have cleaning trial process by our professional engineer to design and propose the best solution to meet and satisfy customer’s needs.

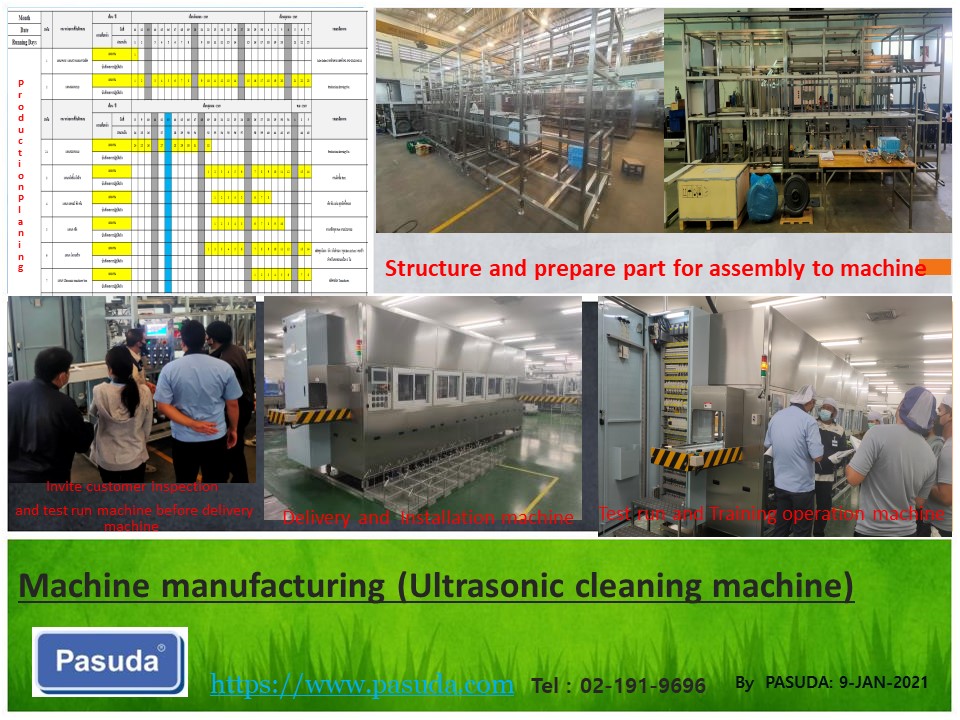

Installation and Training

Move machine into the location

- Connect machine

- Check damage parts and informed to customer (by service report)

- Piping and electrical wiring

- Test run machine

- Report by service report and keep record in the Pasuda Maintenace History (PMH)

Training Operation and Maintenance Machine

- Operation Training (In-House Training at site)

- Maintenance Training (For customer maintenance team)

- Prepare maintenance documents and training at the machine

- Same time with Inspect (Every 6 months)

Improve machine performance

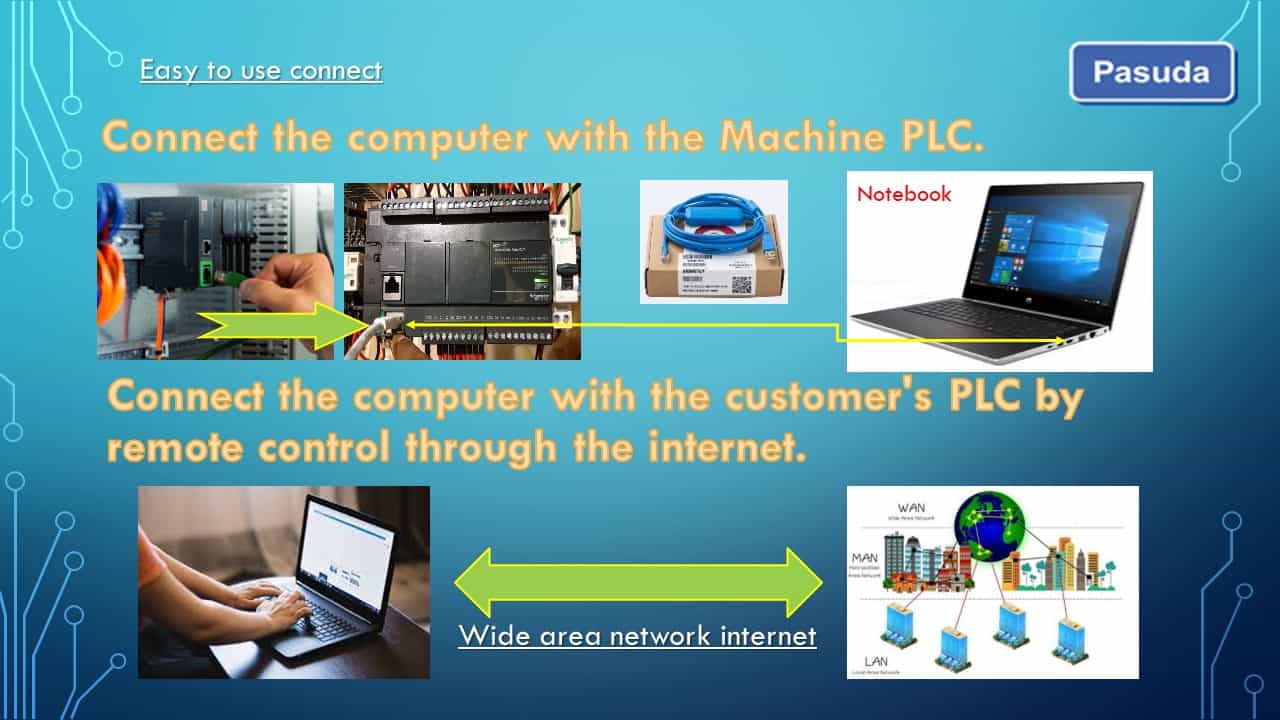

Remote access and support

Control, manage, monitor and repair computers, mobile devices, networks and data cable

Team-Viewer

It is the world’s first remote support technology to allow screen sharing on devices.

- Used for connection of 2 or more computers. But in different positions from software that is used to connect to each other only between computers It supports connection with smartphones and various IoT devices, and in 2019 has been developed to TeamViewer 15. The program supports 30 languages, including Thai.

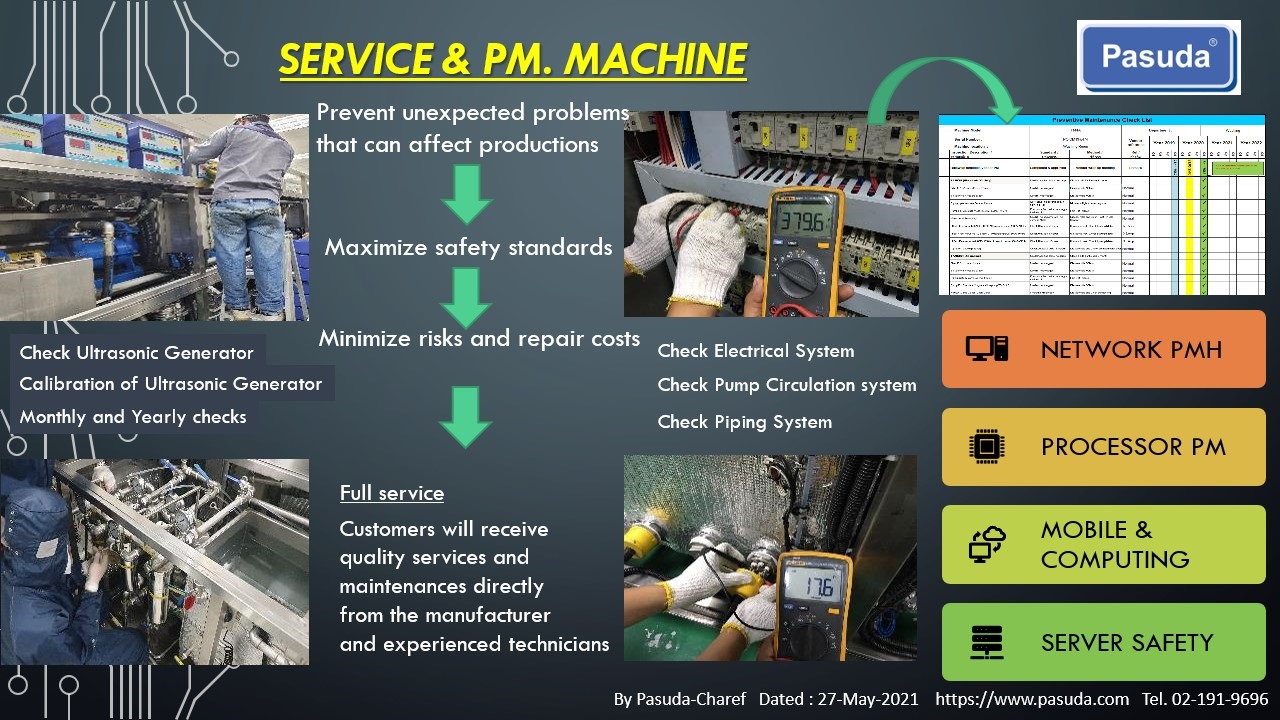

Preventive and corrective maintenance

Check machine conditions

- Inspection: Check all spec of Machine

- Inform customer by Report

- Customer confirmed (Order Spare Part)

- Recommend and replacing parts in case of damage

- Calibrate some parts

- Report by service report and keep the record in the Pasuda Maintenace History (PMH)

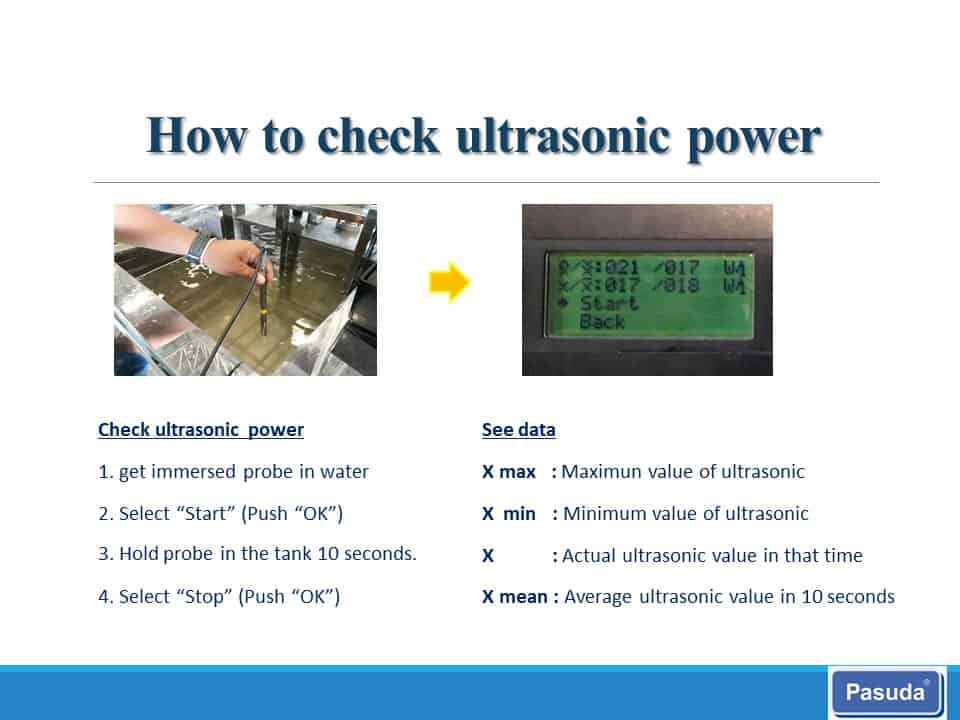

Check Ultrasonic

- Check Ultrasonic Power by UPC-3000 (Ultrasonic Process controller)

Condition of Checking –>

- On Ultrasonic 100% (Do Not using Sweep function)

- Temperature of Water (Liquid) : Follow Temp, Process of Each Tank

- Location of Prob : Middle of Tank

- Off Agitation Durling Check by UPC-3000

- Check Actual Power in Tank (5 Points)

- Time for checking 10 Second Per Point

- Checked the Mode

- Power setting

- Time Setting

- Sweep Setting

- Start/Stop Setting

Summarize report to Customer

- Report by service report and keep record in the Pasuda Maintenace History (PMH)

Moving and Other

Move machine in case of customer request

- Move by moving specialist and standard moving equipment

(considering with safety issue)

Packing and Shipping

- Packing with safety for your product

- Shipping with delivery on time